“Single nanowire radial junction solar cells fabricated using Al catalyzed Si nanowires”, Y. Ke, X. Wang, C. E. Kendrick, Y. A. Yu, S. M. Eichfeld, H. P. Yoon, J. M. Redwing, T. S. Mayer, and Y. M. Habib, Nanotechnology 22, 445401, 2011.

“Single nanowire radial junction solar cells fabricated using Al catalyzed Si nanowires”, Y. Ke, X. Wang, C. E. Kendrick, Y. A. Yu, S. M. Eichfeld, H. P. Yoon, J. M. Redwing, T. S. Mayer, and Y. M. Habib, Nanotechnology 22, 445401, 2011.

1. Department of Materials Science and Engineering, Materials Research Institute, The Pennsylvania State University, University Park, PA 16802, USA

2. Department of Electrical Engineering, Materials Research Institute, The Pennsylvania State University, University Park, PA 16802, USA

3. Illuminex Corp., Lancaster, PA 17601, USA

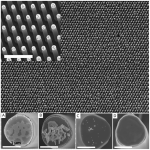

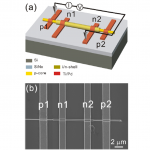

ABSTRACT. Single nanowire radial junction solar cell devices were fabricated using Si nanowires synthesized by Al-catalyzed vapor–liquid–solid growth of the p+ core (Al auto-doping) and thin film deposition of the n+-shell at temperatures below 650 ◦C. Short circuit current densities of ∼11.7 mA /cm2 were measured under 1-sun AM1.5G illumination, showing enhanced optical absorption. The power conversion efficiencies were limited to <1% by the low open circuit voltage and fill factor of the devices, which was attributed to junction shunt leakage promoted by the high p+ /n+ doping. This demonstration of a radial junction device represents an important advance in the use of Al-catalyzed Si nanowire growth for low cost photovoltaics.