“Faceting control in core-shell GaN micropillars using selective epitaxy“, S. Krylyuk, R. Debnath, H. P. Yoon, M. R. King, J. Ha, B. Wen, A. Motayed, and A. V. Davydov, APL Materials 2, 106104, 2014.

“Faceting control in core-shell GaN micropillars using selective epitaxy“, S. Krylyuk, R. Debnath, H. P. Yoon, M. R. King, J. Ha, B. Wen, A. Motayed, and A. V. Davydov, APL Materials 2, 106104, 2014.

1. Materials Science and Engineering Division, National Institute of Standards and Technology, Gaithersburg, Maryland 20899

2. Institute for Research in Electronics and Applied Physics, University of Maryland, College Park, Maryland 20742

3. N5 Sensors, Inc., Rockville, Maryland 20852

4. Center for Nanoscale Science and Technology, National Institute of Standards and Technology, Gaithersburg, Maryland 20899

5. Maryland Nanocenter, University of Maryland, College Park, Maryland 20742

6. Northrop Grumman ES, Linthicum, Maryland 21090

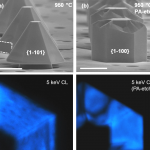

ABSTRACT. We report on the fabrication of large-area, vertically aligned GaN epitaxial core-shell micropillar arrays. The two-step process consists of inductively coupled plasma (ICP) etching of lithographically patterned GaN-on-Si substrate to produce an array of micropillars followed by selective growth of GaN shells over these pillars using Hydride Vapor Phase Epitaxy (HVPE). The most significant aspect of the study is the demonstration of the sidewall facet control in the shells, ranging from {1 1̄ 01} semi-polar to {1 1̄ 00} non-polar planes, by employing a post-ICP chemical etch and by tuning the HVPE growth temperature. Room temperature photoluminescence, cathodoluminescence, and Raman scattering measurements reveal substantial reduction of parasitic yellow luminescence as well as strain-relaxation in the core-shell structures. In addition, X-ray diffraction indicates improved crystal quality after the shell formation. This study demonstrates the feasibility of selective epitaxy on micro-/nano- engineered templates for realizing high-quality GaN-on-Si devices.